3D-Printing

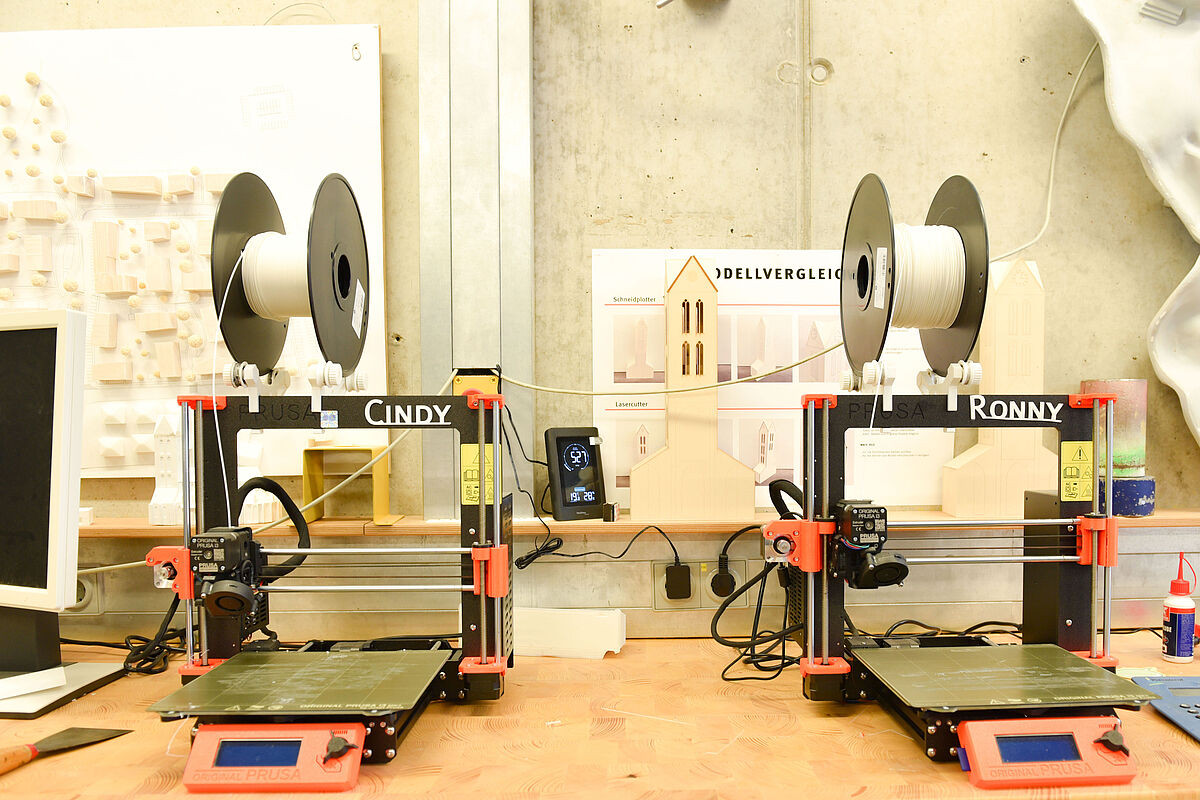

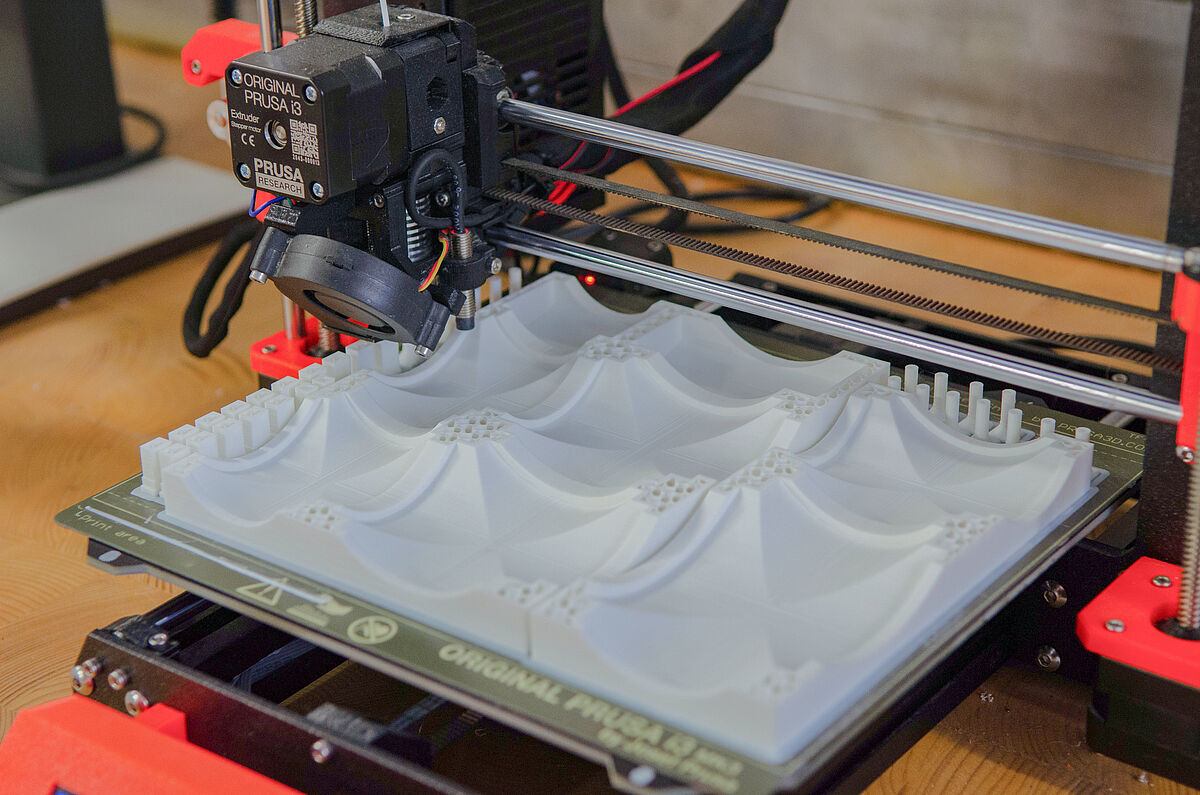

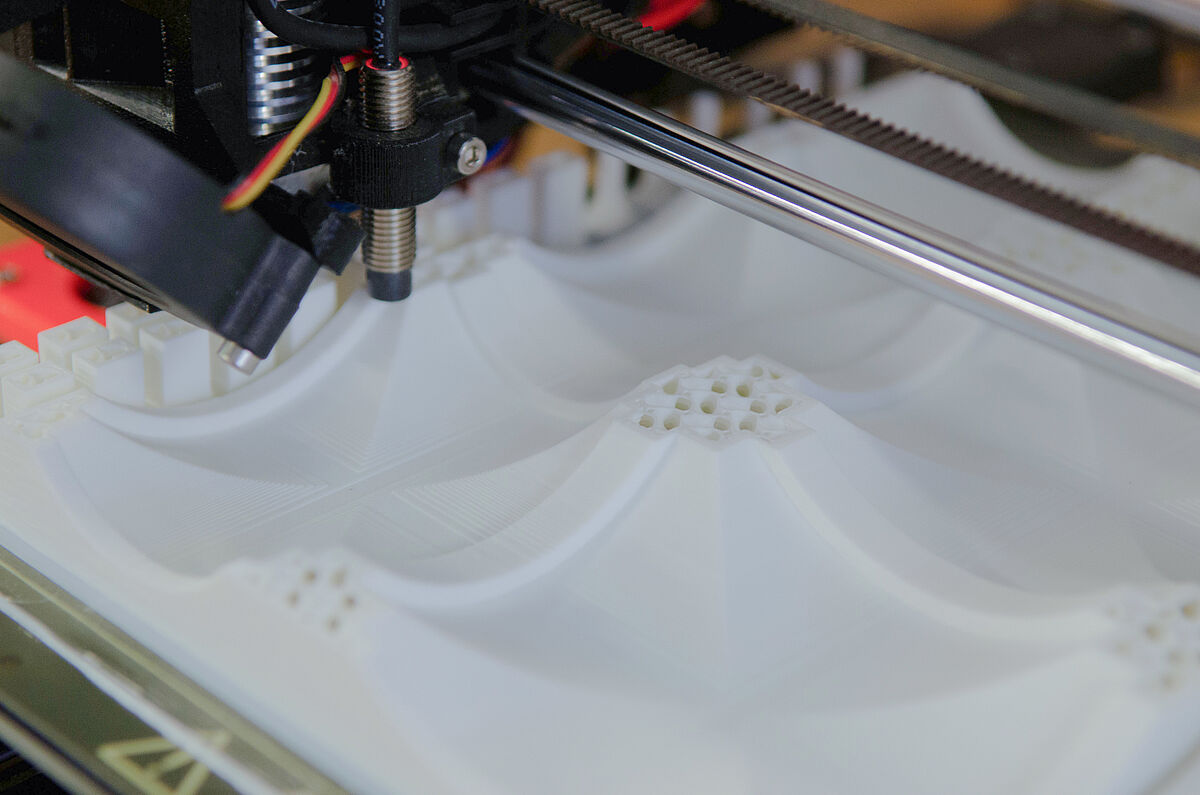

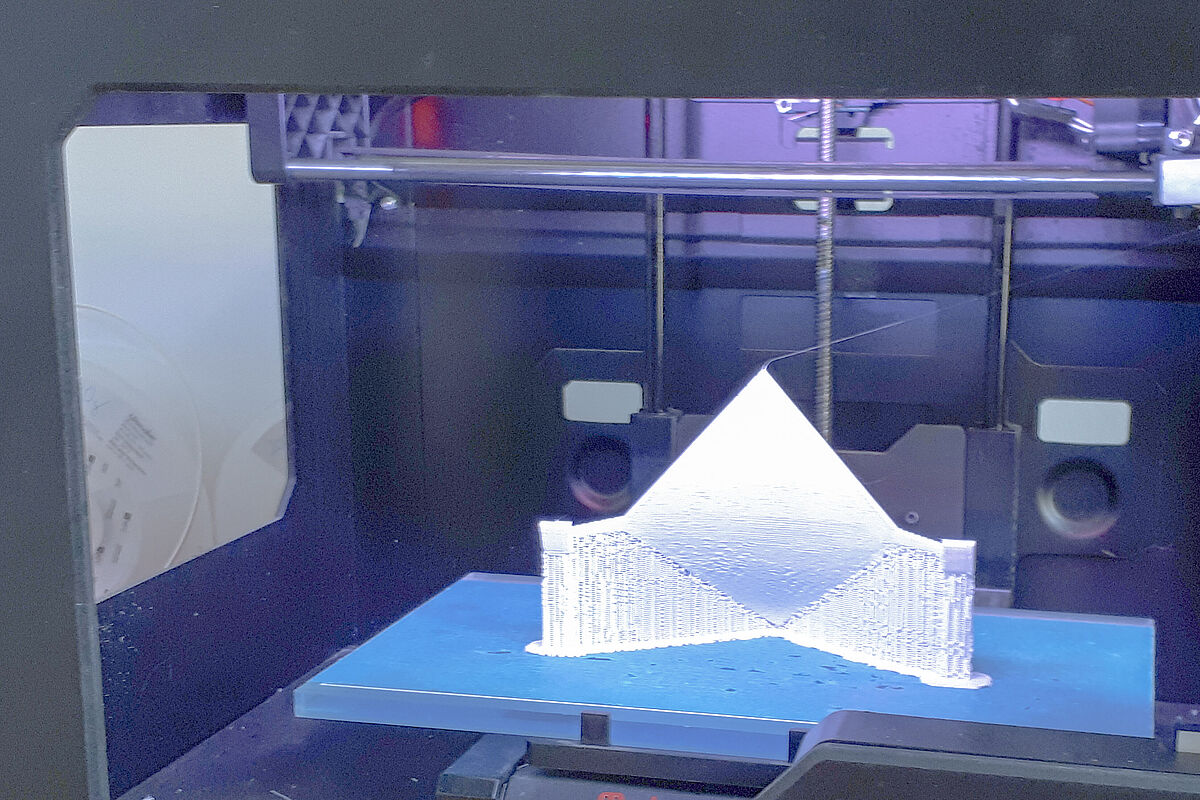

At the Faculty of Architecture and Design we have various different types of 3D printing devices available: Filament and resin printers of various sizes. Detailed descriptions of the printers and the corresponding manufacturer software can be found on StudIP under Model-making workshops.

Book your consulting over Stud.IP »

Model making workshops, directly to the event, resources, choose a workplace and register

How to get ready?

- Data check: We offer you a personal appointment to discuss your project in advance. You will receive direct feedback so that you can optimise and, if necessary, adjust your data. This allows us to avoid complications later on and shorten the overall project phase. The data check forms the basis for all further steps.

- CAD-Files: The basis is formed by 3D drawings of closed solids. The correct STL files created from these are sent to 3d-drucker-fg@hs-wismar.de for printing. Data transfer via removable media is not permitted.

- Material costs: Materials are sold via the material system at material.fg.hs-wismar.de/secure, where the current material prices can also be viewed.